Gasification has gained significant attention in recent years for its ability to convert biomass and waste into syngas. This article provides a comprehensive understanding of gasification by exploring its historical background, key concepts, main discussion points, case studies, current trends and developments, challenges or controversies, future outlook, and a conclusion summarizing the main points discussed.

Contents

Introduction

Gasification is an innovative technology that offers a sustainable solution to waste management and energy generation. By converting biomass and waste into syngas, gasification presents a range of potential benefits and applications. This article aims to shed light on the significance and potential of gasification by exploring its key aspects.

Historical Background

Gasification has a long history dating back to the early 19th century when it was first used to produce town gas for lighting and heating purposes. Over the years, significant advancements and milestones have shaped the field of gasification. From the development of fixed-bed gasifiers to the introduction of fluidized-bed gasifiers, gasification technology has evolved to become more efficient and versatile.

Key Concepts and Definitions

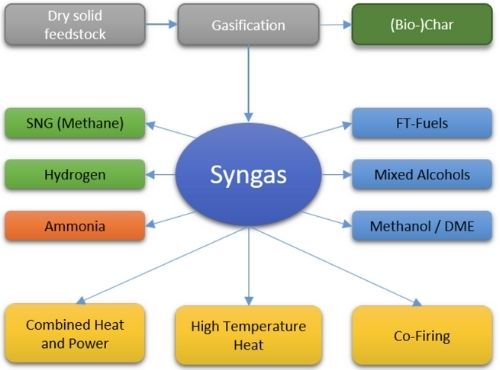

To fully understand gasification, it is important to define the key concepts associated with it. Gasification is a thermochemical process that converts carbon-based materials, such as biomass and waste, into a mixture of gases known as syngas. Syngas typically consists of carbon monoxide, hydrogen, and traces of other gases. Different types of gasifiers, including fixed-bed, fluidized-bed, and entrained-flow gasifiers, operate based on specific principles to facilitate the gasification process.

Main Discussion Points

Gasification Process: The gasification process involves several steps, including drying, pyrolysis, and gasification. Biomass and waste are first dried to remove moisture before undergoing pyrolysis, which breaks down complex organic compounds into smaller molecules. The final stage is gasification, where the carbon-based materials are converted into syngas through a controlled oxygen-starved environment. Optimizing operating conditions is crucial for maximizing syngas production.

Applications of Syngas: Syngas finds various applications in power generation, heat production, and chemical synthesis. Its versatility and lower environmental impact make it a cleaner alternative to fossil fuels. Industries like steel, cement, and transportation can benefit from syngas utilization, reducing their reliance on conventional energy sources.

Benefits of Gasification: Gasification offers several advantages over traditional waste disposal and energy generation methods. It enables the conversion of waste into energy, reducing the burden on landfills and contributing to a more sustainable waste management approach. Additionally, gasification processes hold the potential for carbon capture and utilization, mitigating greenhouse gas emissions.

Case Studies or Examples

Real-world examples of successful gasification projects highlight the effectiveness of this technology. These projects have demonstrated significant outcomes and benefits, such as reduced waste volumes, energy generation, and cleaner emissions. Lessons learned from these case studies contribute to the continuous improvement and refinement of gasification processes.

Current Trends or Developments

Recent trends in gasification technology focus on improving efficiency and scalability. Advancements in gasification processes have resulted in higher syngas yields and reduced environmental impact. Ongoing research and findings contribute to the development of more efficient gasification systems that can handle various feedstocks.

Challenges or Controversies

The widespread adoption of gasification technology faces certain challenges and controversies. Some concerns revolve around the environmental impact and safety of gasification. Striking a balance between energy production and minimizing potential risks is crucial. Ongoing research and efforts aim to address these challenges and provide solutions that ensure the safe and sustainable implementation of gasification technology.

Future Outlook

The future of gasification technology holds immense potential for addressing waste management and energy challenges. Advancements and innovations are expected to further enhance the efficiency and effectiveness of gasification. Synergies with other renewable energy technologies and waste management strategies can create a more sustainable and circular economy.

Conclusion

Gasification offers a sustainable solution to convert biomass and waste into syngas, presenting numerous benefits and applications. By exploring its historical background, key concepts, main discussion points, case studies, current trends, challenges, and future outlook, this article highlights the significance and potential of gasification in addressing waste management and energy challenges. Readers are encouraged to further explore this topic and its potential applications.

References

- Smith, K. R., Haigler, A. H., & Taos, P. (2013). Gasification: An alternative process for energy recovery and disposal of municipal solid waste. Environmental Progress & Sustainable Energy, 32(3), 716-722.

- Li, Q., Li, H., & Zhang, D. (2017). Recent developments in biomass pyrolysis and gasification. AIMS Energy, 5(2), 293-324.

- Bridgwater, A. V. (2015). Review of fast pyrolysis of biomass and product upgrading. Biomass and Bioenergy, 38, 68-94.